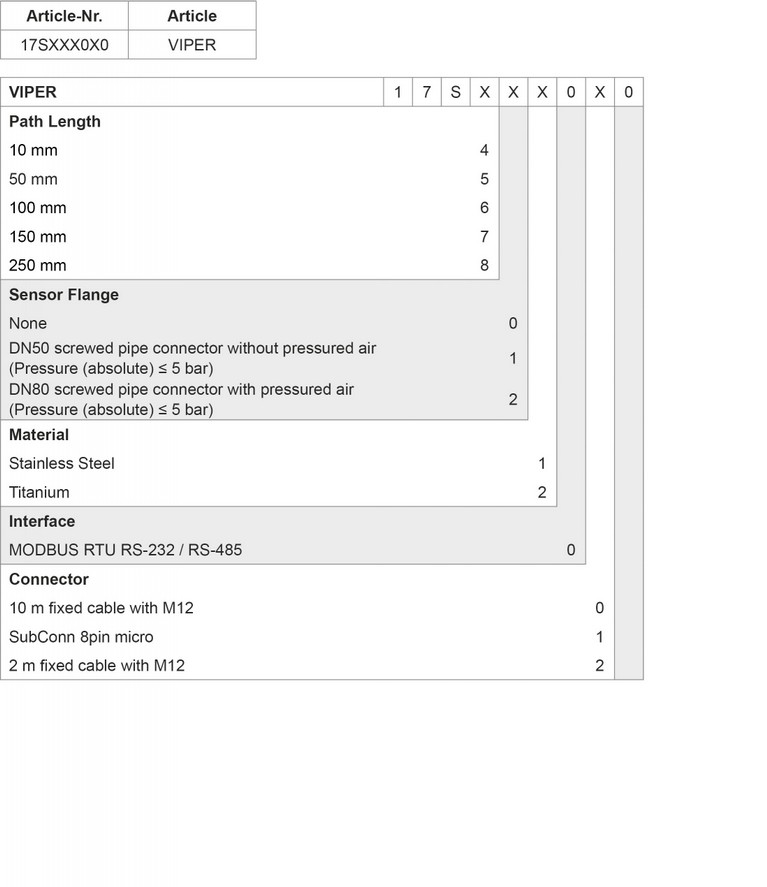

VIPER

VIS photometer for measurements of hyperspectral attenuation and transmission between 360 and 720 nm.

VIPER measures hyperspectral attenuation and transmission coefficients in the wavelength range of 360 nm and 720 nm, enabling detailed determination of multiple parameters at the same time. The light source is provided by 5 selected, energy-saving LEDs that warranty a long service life and stable measurement data. VIPER can be used in different media as it is available in multiple path lengths, both in stainless steel or titanium housing.

Typical applications for VIPER are water quality monitoring, color measurements of aqueous solutions or quality monitoring of drinking water. Like all TriOS sensors, VIPER is equipped with nano coated optical windows that protects from fouling. Additional parameters can be installed by means of software if necessary at a later time.

VIPER

Benefits

- without sampling and sample preparation

- without delay

- without reagents

- optical windows with nano coating

- LED technology

Areas of application

- Environmental monitoring

- Drinking water monitoring

- Colour measurement

- Quality assurance

- Petrochemistry

Parameters

- True color410

- Pt-Co color390

- Pt-Co color455

- Cr-Co color380

- Cr-Co color413

- SAC436

- SAC525

- SAC620